Physical Expansion

The expanded plastic in Physical Foam does not undergo any chemical alteration since the expansion process is totally "physical", natural, contrary to crosslinked foam (crosslinked foam)< / i> which, on the other hand, are chemically treated and therefore the final product obtained is not recyclable. The Physical Foam on the other hand is 100% recyclable and regenerable since the polymer of Polypropylene (PP) and Polyethylene ( PE) keeps its structure intact even after the physical expansion process, regardless of the degree of density adopted for the different products.

Polypropylene and Polyethylene

Polyolefin polyolefin foams can boast an imposing presence on the market, thanks to the vastness of their possible applications. In particular, expanded thermoplastic polymers play a leading role in industrial manufacturing, where the increasingly common polyolefins (polyethylene and polypropylene) are progressively gaining market share.

Funds Por Fesr 2014/2020

The Regional Tender POR FESR 2014/2020 Action 3.1.1 made it possible for the Proxital Srl company to reduce the use of raw materials in the company's production cycle, through the reduction of production waste obtainable with:

- reduction of machine set-up changes as the type of production to be performed varies;

- recycling of production waste through regeneration for their reuse in the manufacturing process.

Specifically, the investment consisted in the purchase of:

- Wrapping machine (conceived and designed on the specific needs of the company), capable of processing roll heights greater than standard machines (up to 3 m);

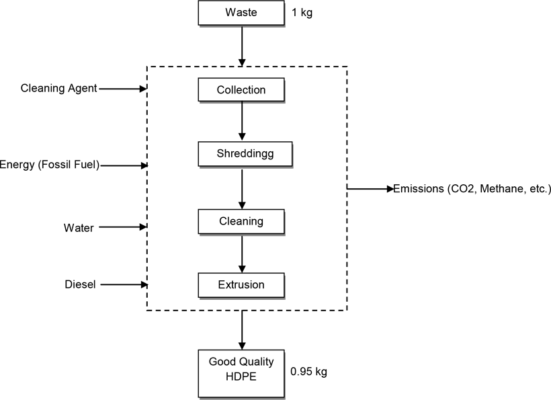

- Shredder and granulation plant, for the regeneration of production waste;

- Automated pneumatic system for transporting processing waste to the regeneration department.

The subsidy granted by the Veneto Region amounts to 67,500.00 euros.

Go UP